Link to: Copaltite

DIRECTIONS FOR USE

Link to: Copaltite

COPALTITE™

- To seal, apply a thin coat of COPALTITE to both surfaces. COPALTITE won’t seal effectively if foreign matter is present. To ensure a direct bond to the metal surfaces, make sure they’re clean and dry, with all dirt, oil, grease, or moisture removed before applying.

- The heat of at least 212°F must be applied to set COPALTITE. At this temperature, set-up time could take up to 4 hours. At 300°F, set-up time is approximately 30 minutes.

- If a joint is to hold high pressure at an elevated temperature, heat should be applied without pressure until the COPALTITE has set.

- If using COPALTITE for a steam application, apply it to the joint, tighten and heat the joint by turning on the steam at little or no pressure for about six hours, preferably overnight. The COPALTITE sealed joint will then withstand high temperatures and pressures.

- If COPALTITE has hardened, a wire brush and alcohol may be used to remove the product.

- COPALTITE should be stored in a cool, dry place. The shelf life is one year from the date of manufacture when stored at 72°F.

Link to: About

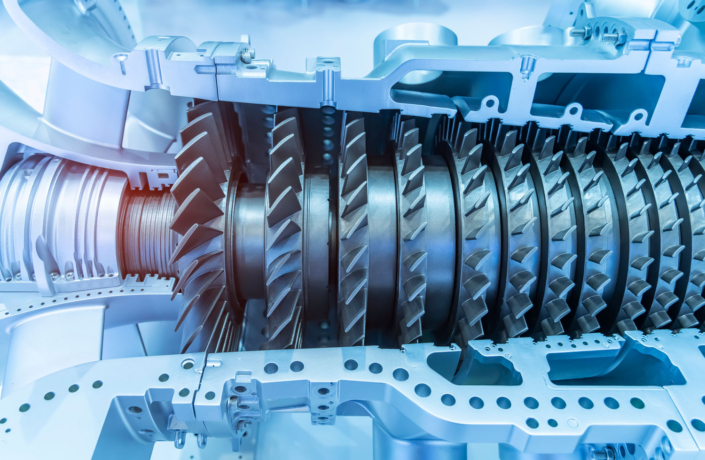

Instructions for sealing turbine horizontal joints

- After the casing has been lifted, clean the upper and lower flange surface of all foreign matter. Be sure the surface area is clean, dry, and free of any oil. Wipe clean and dry.

Grooved turbines with smooth surface flanges

- Apply a thin film of liquid COPALTITE to upper and lower flange surfaces, but not in the grooves. Allow the material to become tacky, then lower the casing and bolt down. This will make an actual tight joint without considering grooves.

- While the turbine is being warmed up before being placed in operation, and while the turbine is hot, a pressure gun capable of producing at least 4000 psi should be used for dispensing COPALTITE cement into the grooves. Filling the grooves should be done around the entire turbine in order to secure a uniform and permanent joint. This forms a COPALTITE cement key.

- When dispensing COPALTITE cement into any one groove outlet, remove the nest plug (which we will call No. 1) in the direction the groove is being pumped. When the COPALTITE begins to flow from the No. 1 opening, close the same and also remove the gun and close the opening. Start pumping into the next opening (which we will call No. 2), at the same time removing the plug from the No. 3 opening. Continue until all plugged openings have been pumped.

Grooved turbines with scored surfaces flanges

- In the event the flange surfaces are scored, then substitute COPALTITE cement in the place of COPALTITE liquid for making flange joint. Use COPALTITE cement for pumping groove.

Link to: Nepseal 30

NEPSEAL 30™

- Ensure the surface is clean and dry before application.

- Store any unused product in a cool, dry place, tightly sealed.

- Follow safety precautions, including wearing gloves.

- Can be applied at ordinary temperature.

- Can be applied by knife or spatula.