Commonly asked questions are addressed here. For additional information, click here to contact us directly.

Who invented COPALTITE?

Inspired by sealant compound he originally encountered in pre-WWII Germany, Maryland native C. Gibson Ford developed a similar product to meet the growing need for sealants able to hold high temperatures and pressures on turbine joints, diesel engines, cylinder heads, and other superheated steam pressures. In 1934, Ford founded a DC- based firm and thereafter commenced domestic production of a sealant that today, some nine decades later, continues to be the “go-to” for companies and governments needing a compound that can “seal the deal” under high pressures and temperatures.

How thick should COPALTITE™ be applied when used as a gasket coating?

A film of COPALTITE should be applied when used as a gasket coating. The COPALTITE should be applied to both surfaces of the gasket and allowed to become quite tacky before tightening down the surfaces.

How thick a coating of COPALTITE should be applied without a gasket?

With or without a gasket, only a thin film of COPALTITE should be applied when used as a gasket coating. The COPALTITE should be applied to both surfaces of the gasket and allowed to become very tacky before tightening down the surfaces.

Should the joint be made up tightly while the material is still moist or should it be permitted to dry?

It should not be tightened down immediately, allowing sufficient time for the thinner content to evaporate. This not only ensures a better joint but also keeps the COPALTITE from being forced out when the joint is tightened.

If COPALTITE is used on flanges, should both faces be coated?

Absolutely; give both faces of the flange a thin coat of COPALTITE.

Will COPALTITE freeze a joint after being in service for an extended period of time?

Not at all. COPALTITE remains plastic indefinitely, and all joints are easily broken.

Will a wide range of temperatures cause COPALTITE to become hard and brittle?

No. COPALTITE will remain plastic under any conditions with temperatures varying from – 315°F to 1500°F

When storing COPALTITE, should any special precautions be taken?

Store it in a cool place with an ambient temperature of 72º F away from heat or sunlight.

How should surfaces be prepared for COPALTITE application?

To secure a direct bond to the metal surface, carefully remove all dirt, oil, grease, or moisture before applying COPALTITE.

Will extreme vibration, contraction or expansion impair the security of the joint?

No, the plastic quality of COPALTITE prevents any cracking or breaking due to extreme vibration, contraction, or expansion.

How should heat be applied?

Use a heat gun, infrared lights, or an oven for small parts. Care should be taken if an open flame (e.g., a torch) is used, because COPALTITE is flammable. Heat the metal away from the COPALTITE joint, then metal can be used to conduct heat to the joint and affect a cure.

Are there any special instructions for using COPALTITE on large diameter flanges?

Cover both faces with COPALTITE cement of minimum thickness, then bring the faces into contact– but do not tighten the joint for approximately one hour. Additional security may be achieved by slotting both inside flange faces – with the slot staggered.

How do I know how much COPALTITE is needed for my application?

One quart of COPALTITE covers 3,091 square inches. One tube of COPALTITE covers 88 square inches. Ten quarts cover exactly 20 square meters.

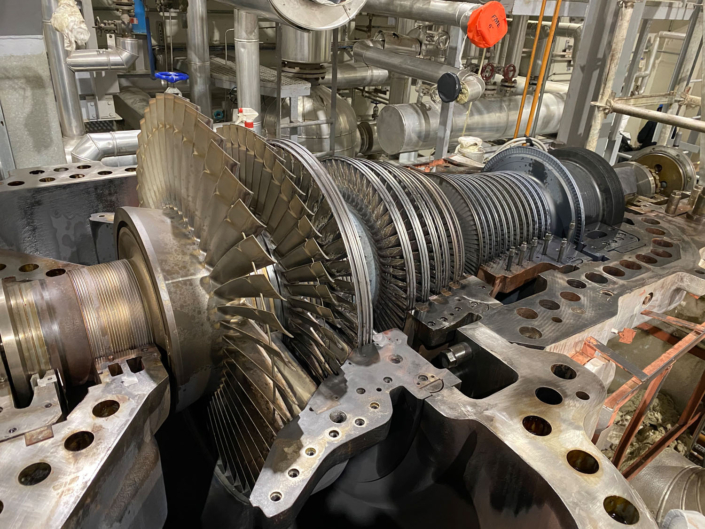

What’s the best process to follow for sealing turbine horizontal joints?

After the casing has been lifted, clean the upper and lower flange surface of all foreign matter. Be sure the surface area is clean, dry, and free of any oil.

For grooved turbines with smooth surface flanges:

- Apply a thin film of liquid COPALTITE to upper and lower flange surfaces, but not in the grooves. Allow the material to become tacky, then lower the casing and bolt down. This will make an actual tight joint without considering grooves.

- While the turbine is being warmed up before being placed in operation, and while the turbine is hot, a pressure gun capable of producing at least 4000 psi should be used for dispensing COPALTITE cement into the Filling the grooves should be done around the entire turbine to secure a uniform and permanent joint. This forms a COPALTITE cement key.

- When dispensing COPALTITE cement into any one groove outlet, remove the nest plug (which we will call No. 1) in the direction the groove is being pumped. When the COPALTITE begins to flow from the 1 opening, close the same and remove the gun and close the opening. Start pumping into the next opening (which we will call No. 2), at the same time removing the plug from the No. 3 opening. Continue until all plugged openings have been pumped.

For grooved turbines with scored surfaces flanges:

In the event the flange surfaces are scored, then substitute cement in the place of COPALTITE liquid for making flange joint. Use COPALTITE cement for pumping groove.